Prof. Jang Min’s Research Team (Department of Environmental Engineering) Develops High-Efficiency...

- admin

- 2021-11-10

- 3674

Prof. Jang Min’s Research Team (Department of Environmental Engineering) Develops High-Efficiency Material for Manganese Removal in Water

Professor Jang Min’s research team (Department of

Environmental Engineering), Jang Seok-Beom (first author) and research

professor Jong Cho-Eun (co-corresponding author), conducted a research project

with a magnesium hydroxide-coated medium (Flower like Magnesium Hydroxide

coated) in polyurethane that effectively removes manganese in water.

Polyurethane (hereinafter FMHP) was developed. The results were published in

the Journal of Hazardous Materials (IF: 10.588, JCR top 3.64%), a scientific

journal in the field of environment.

Manganese is the 12th

most abundant element in the earth's crust and exists mainly in the form of

ore. Long-term or high exposure to manganese can cause chronic manganese

poisoning and neurological damage such as Parkinson's disease.

Adsorption, which is

the most widely used among existing water treatment technologies, has

limitations such as low manganese selectivity and some ionized manganese

remaining. In addition, the removal of manganese through oxidation among widely

used technologies generates a large amount of sludge (sediment) and has a

disadvantage due to the cost of post-treatment. Therefore, it is inevitable to

develop a practical, simple, and high-efficiency technology for the treatment

of manganese.

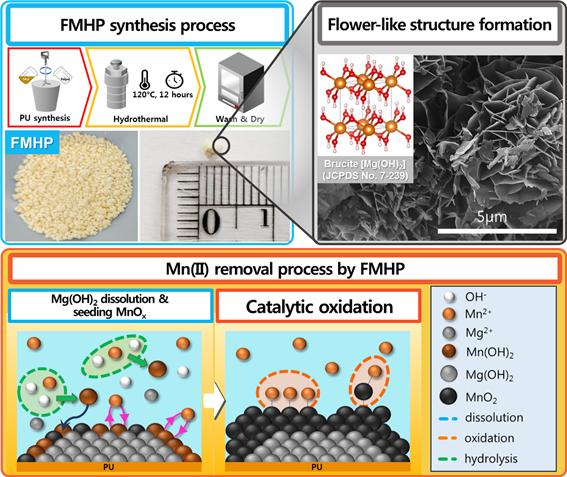

When magnesium

hydroxide undergoes a hydrothermal synthesis process, related studies have been

actively carried out as the plate-shaped magnesium hydroxide forms a

flower-shaped three-dimensional structure with a maximized surface area due to

its own aggregation and electrostatic repulsion. In particular, research on

removing heavy metals by supporting magnesium hydroxide on the surface of

polyurethane has been continuously conducted.

Professor Jang Min’s

research team found that by supporting magnesium hydroxide on the surface of

polyurethane, the adsorbed manganese is oxidized rather than simply adsorbed to

dissolved manganese to form a manganese oxide layer. In this study, the effect

of the reaction between magnesium hydroxide and dissolved manganese and the

formed manganese oxide layer on the manganese removal ability was investigated

and confirmed.

Through the results

of this study, the treatment of dissolved manganese with polyurethane loaded

with magnesium hydroxide costs $0.062 million per ton of contaminated water,

proving that it is very economical and effective. It is expected to make a

significant contribution to improving health.

Meanwhile, this study was carried out with the support

of the National Research Foundation of Korea and the Korea Institute of Science

and Technology, and the research results were published online on September 20,

2021 in Journal of Hazardous materials (IF: 10.588), a scientific journal. (Paper

title: In-situ growth of manganese oxide on self-assembled 3D-magnesium

hydroxide coated on polyurethane: Catalytic oxidation mechanism and application

for Mn(II) removal)

■ Web link: https://doi.org/10.1016/j.jhazmat.2021.127267

Manufacturing and properties of magnesium hydroxide-supported polyurethane and the mechanism of manganese removal and in situ formation of manganese removal material by the material