Prof. Park Jae-Young’s Research Team Develops Nanofiber-Based High-Power Nanogenerator and No-Pow...

- admin

- 2021-11-18

- 2344

Prof. Park Jae-Young’s Research Team Develops Nanofiber-Based High-Power Nanogenerator and No-Power Sensor

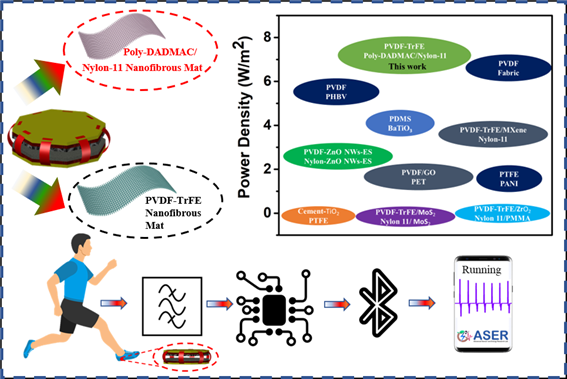

Professor Park Jae-Young's research team (Department of Electronic Engineering) at the university made a composite nanofiber by adding Poly-DADMAC, a cationic monomer, to nylon (Nylon-11), and using it as a cationic charging material, a high-output triboelectric nanogenerator and a separate power supply developed a non-powered pressure sensor that can monitor the movement of the human body in real time without the need for it.

Unlike conventional triboelectric materials, the developed composite nanofiber has a large surface area, high dielectric constant, high surface potential, and high mechanical strength. In particular, since high-output electrical energy can be harvested, it is expected to be utilized as an eco-friendly power source and sensor technology for various portable and wearable devices and industries.

Professor Park Jae-young Park (left) and Ph.D. Student Sohel (right)

As the power consumption of various wearable devices and new Internet of Things (IoT) products that are recently launched in the market is lowered, physical/mechanical energy discarded from the human body and the surrounding environment can be converted into electrical energy to replace the existing rechargeable battery. Energy harvesting technology for use as an eco-friendly power source is being actively studied at home and abroad. In particular, research on triboelectric nanogenerators with a light and simple structure that can produce large amounts of electricity even in human activity and the surrounding environment (small-sized, low-frequency movement) is receiving great attention among them.

After adding Poly-DADMAC, a cationic monomer, to nylon (Nylon-11), the research team developed the world's first composite high-quality nanofibers using electrospinning technology, and applied PVDF-TrFE-based anionic nanofibers together. Thus, a high-output triboelectric nanogenerator was manufactured. The high output of the nanogenerator is due to the three-fold increase in capacitance and permittivity due to the formation of fine dipoles on the surface of the fabricated composite nanofiber. In addition, the composite nanofibers exhibited high durability with mechanical strength about 6 times higher than that of pure nylon nanofibers.

The triboelectric nanogenerator exhibited an output of up to 7.6 W/m2 of power density at a frequency of 12 Hz and a load resistance of 4 MΩ and is power that can directly charge various low-power wearable devices and IoT products. In addition, it was demonstrated that the nano-generator can be utilized as a power-free pressure sensor with a high-pressure sensing sensitivity of 0.01 V/KPa under the pressure range of 0 to 40 kPa. The research team successfully demonstrated an experiment that monitors human movement in real time, such as walking, running, and jumping slowly or quickly through a smartphone app. In addition, the composite nanofiber developed by this research team and its manufacturing method can be easily utilized not only for the application of nanogenerators, but also for the development of various flexible sensors and energy storage devices.

Meanwhile, this research was carried out with the support of the National Research Foundation (NRF-2020R1A2C2012820) with the funding of the government (Ministry of Science and ICT), and the research results were published by ELSEVIER, the world's leading energy research journal. (Nano Energy, IF: 17.8).

https://doi.org/10.1016/j.nanoen.2021.106300

?Conceptual diagram of nylon composite nanofiber-based nanogenerator and unpowered pressure sensor and comparison of characteristics with other research results